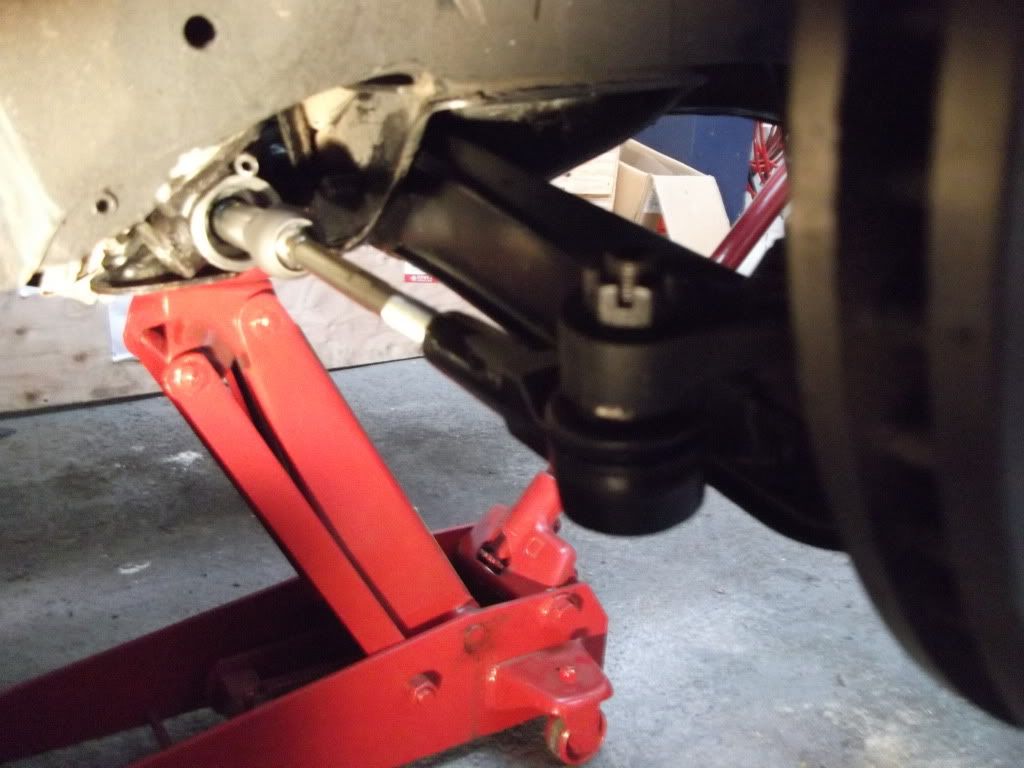

Got the first radius rod bracket made up today, looks like it's going to work pretty well. I had to chop the cup for the bush off the factory mount but that's no biggie. Haven't got everything bolted up tight yet as I need to get some more nuts and bolts.

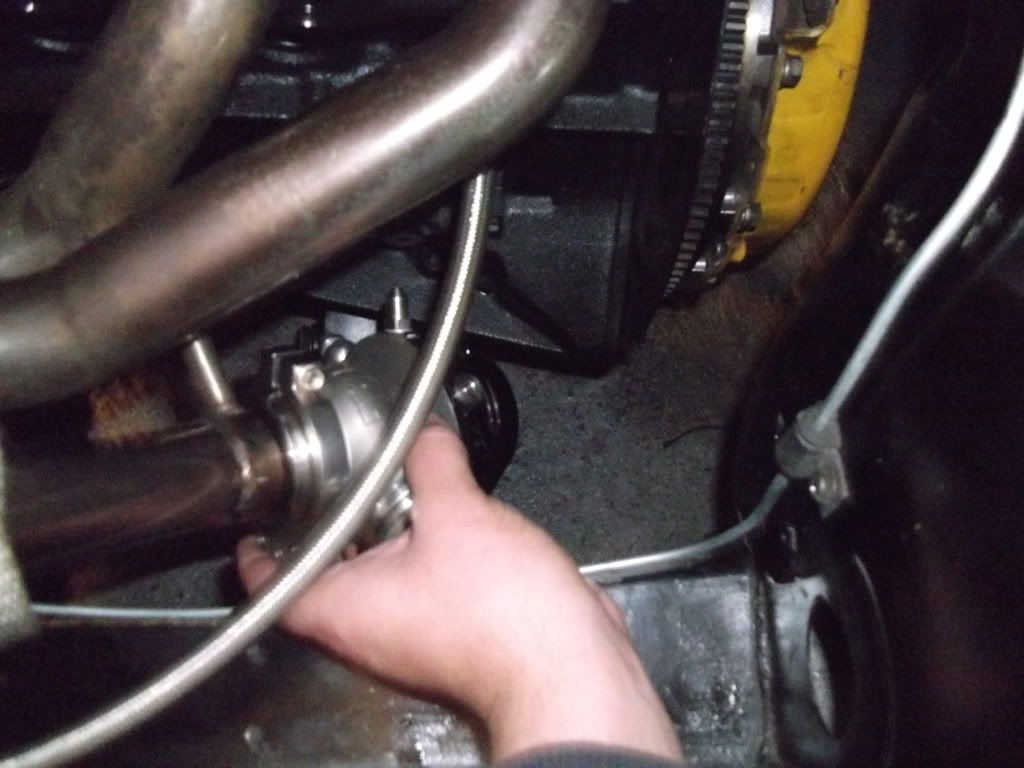

Mocked up the rack end and lengthened tie rod end, I might get some rack end spacers not for extra lock but to help with the thread problem too.

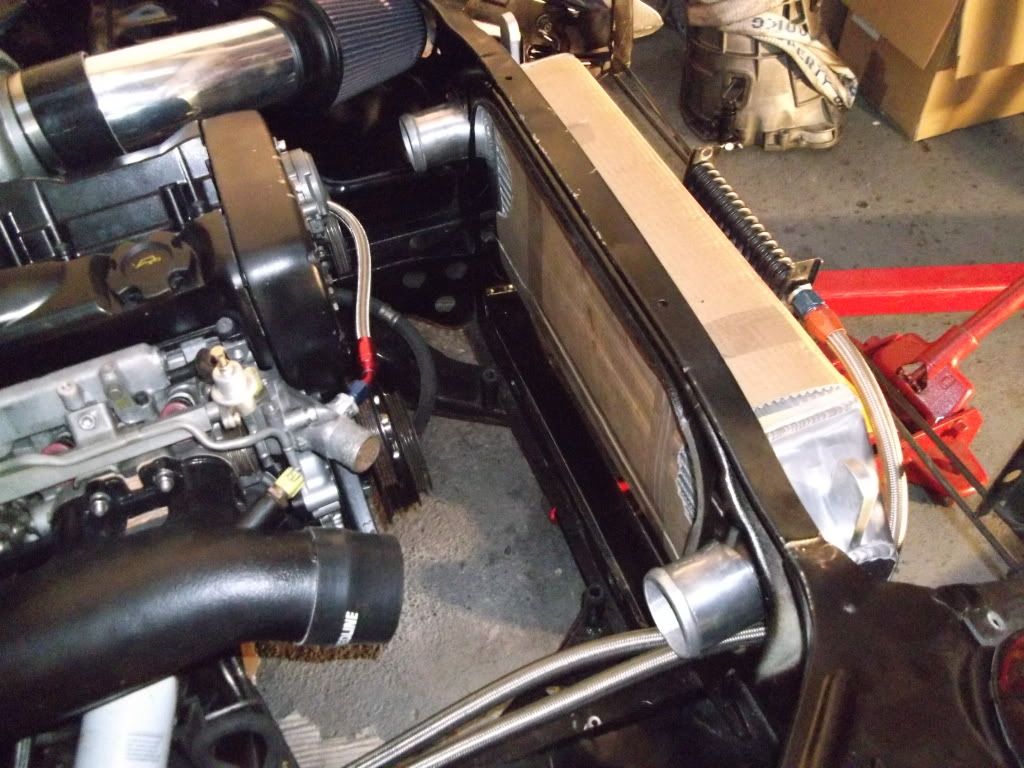

This is how the motor is sitting at the moment, I've got to get the top radiator outlet welded up before I can finish the water line for the turbo.

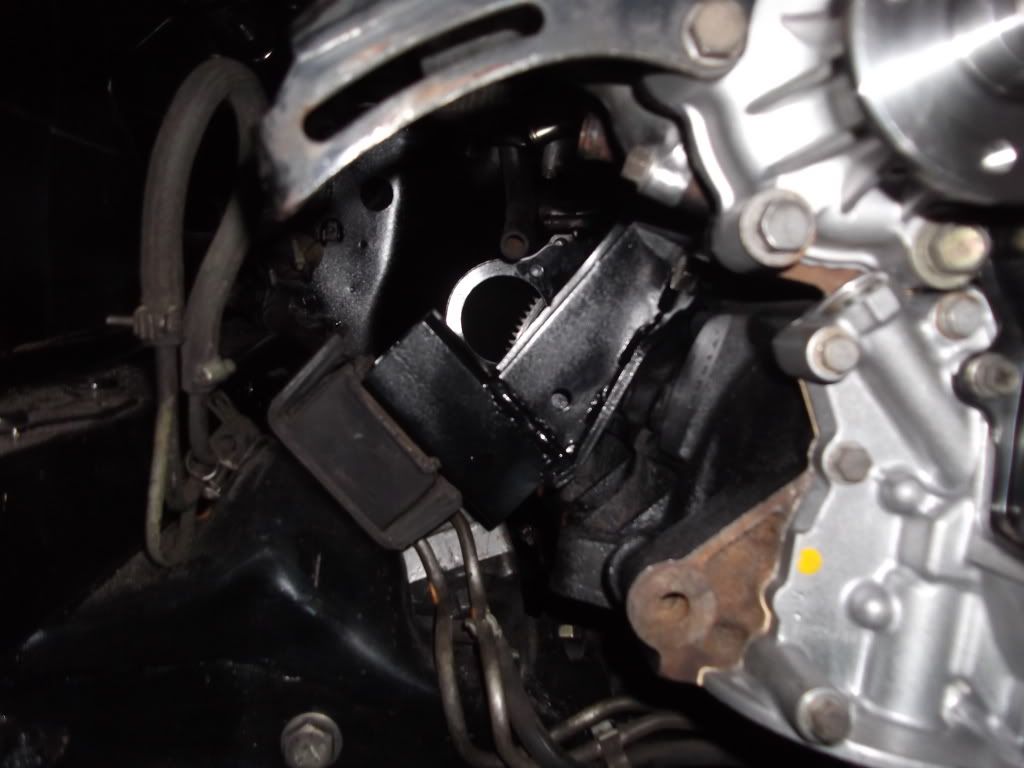

This is how the finished engine mount came out.

So tomorrows mission is to start on the gearbox mount.