well re designing a camber plate for one vehicle to another is no easy task (datsun boy - this is why you haven't received a file yet )

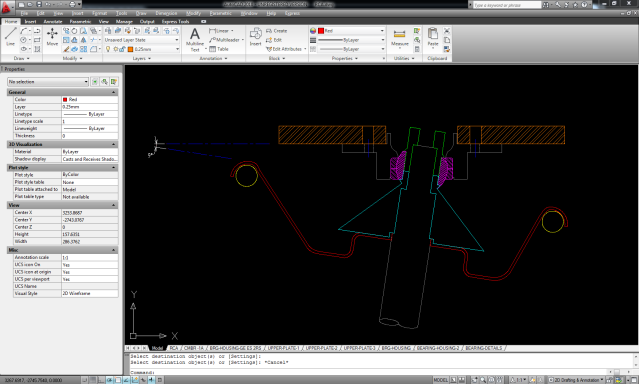

I have been fiddling around with the spring spacer design to suit my Z31 struts and springs and also trying to work in the maxim misalignment angle possible without things hitting

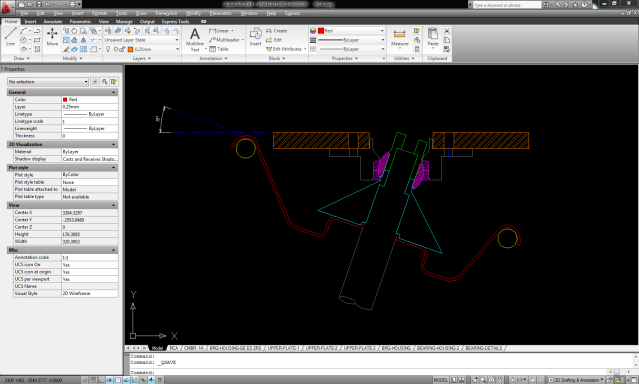

every-time I do a re design i get a little closer to things working nicely and I think of something else I need to check

If you see where I'm at for the moment this all looks well and good to go have it made, but really i know i should take measurements off the car and plot out all the suspension pivot points so that I can make fully sure that the Bearing has full contact at maximum camber ( before the spring hits the strut tower )

I think that I am much more likely to gain a CERT if i have evidence that these important safety aspects have been checked thoroughly.

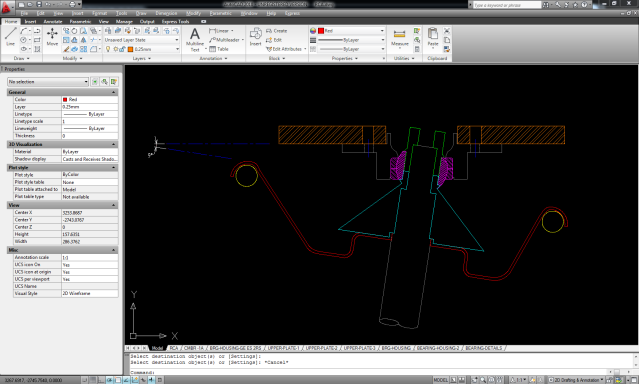

Picture 1 Shows the shock moving through all of the bearings travel which gives me 9deg of angle from the shock to the camber plate

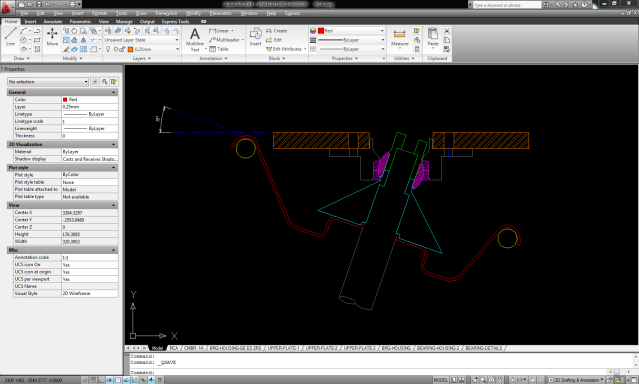

Picture 2 Shows the scenario WE DON'T WANT which is where the bearing starts to travel out of its housing and does not have full surface contact > potential leading to something failing = bad !! note the extra 10deg giving a total of 19deg

I have clearance d the spring spacer & shim nut to allow more travel without it hitting the bearing to aid installation and you want a big more wiggle putting things together.

so long story short is i need to draw up my Car's entire front end to make sure i can get some decent camber while things maintain proper contact.

I am entirely sure 9deg of movement is HEAPS but its better to check now than have it made and it dosn't work properly