Had a look over the block, can't see anything other than a couple of new scratches in the bores that weren't there last time, none of them feel that deep so I think I'll just ignore them for the moment.

When I pulled the exhaust manifold off the head there was a bit of oil in the exhaust port of cylinder 1 and a bit of oil in the exhaust manifold, I can't pinpoint exactly where the oil came from but it might explain the higher compression test reading on number one compared to the other cylinders (which would also indicate poor ring sealing). I removed the cam and took the bucket, retainers and springs off the first two valves, the valves seem a little loose in the stem seals to me. Will take the rest of them apart later on tonight maybe.

Seems to be lots of carbon everywhere, will probably have to get the head tanked again to get rid of it all.

DJZ's 280ZX

Re: DJZ's 280ZX

Got the head pretty much all the way apart, need to remove the rest of the inlet manifold before I can get it tanked.

Sent the damaged Tomei inlet cam to Kennelly Cams, he welded up the damaged lobe and reground it, the repair looks pretty good.

I set up the other head that I've almost finished porting on the mill to try and clearance it for the cam lobes, was a bit of a waste of time, I spent bloody ages trying to bolt it down to the bed but I need to set it up on 4 different angles which I don't really have the right stuff for and I can only do one side of 10 out of 12 notches at a time, I ended up just doing them with the die grinder and will finish them off with a sanding roll. I also drilled out the oil return ports, I need to get a long 10mm end mill to finish one of them off.

I'm not actually sure where I'm going with this thing, it really needs to come off the road at some stage soon and the windscreen is leaking worse than ever. I might not actually put the motor back together at the moment and concentrate on finishing the white car off.

Also noticed that the exhaust manifold is starting to crack on one of the welds near the collector, looks like they didn't put enough filler metal in.

Sent the damaged Tomei inlet cam to Kennelly Cams, he welded up the damaged lobe and reground it, the repair looks pretty good.

I set up the other head that I've almost finished porting on the mill to try and clearance it for the cam lobes, was a bit of a waste of time, I spent bloody ages trying to bolt it down to the bed but I need to set it up on 4 different angles which I don't really have the right stuff for and I can only do one side of 10 out of 12 notches at a time, I ended up just doing them with the die grinder and will finish them off with a sanding roll. I also drilled out the oil return ports, I need to get a long 10mm end mill to finish one of them off.

I'm not actually sure where I'm going with this thing, it really needs to come off the road at some stage soon and the windscreen is leaking worse than ever. I might not actually put the motor back together at the moment and concentrate on finishing the white car off.

Also noticed that the exhaust manifold is starting to crack on one of the welds near the collector, looks like they didn't put enough filler metal in.

Re: DJZ's 280ZX

Got the head back from Fleming's, he tanked it for me, cleaned the face and inspected it, he couldn't find anything wrong with it.

Took the compressor cover off the turbo to see how much oil was actually in there and there wasn't a lot, gave it a good clean out.

I've been thinking about what to do with the motor, I might pull the bottom end out of the car and combine the good crank and oil pump out of this one with the other block and CP forged pistons that are coated that have been at the engine shop for about 18 months now, I'll get some forged rods too. I've got a set of ARP main studs and the ARP head studs that I was running on the original motor.

While I've had access I decided to redo the engine mounts, I was never happy with my box section mount, the position was fine it was just the construction of the mount and the packing that I had to use that wasn't good.

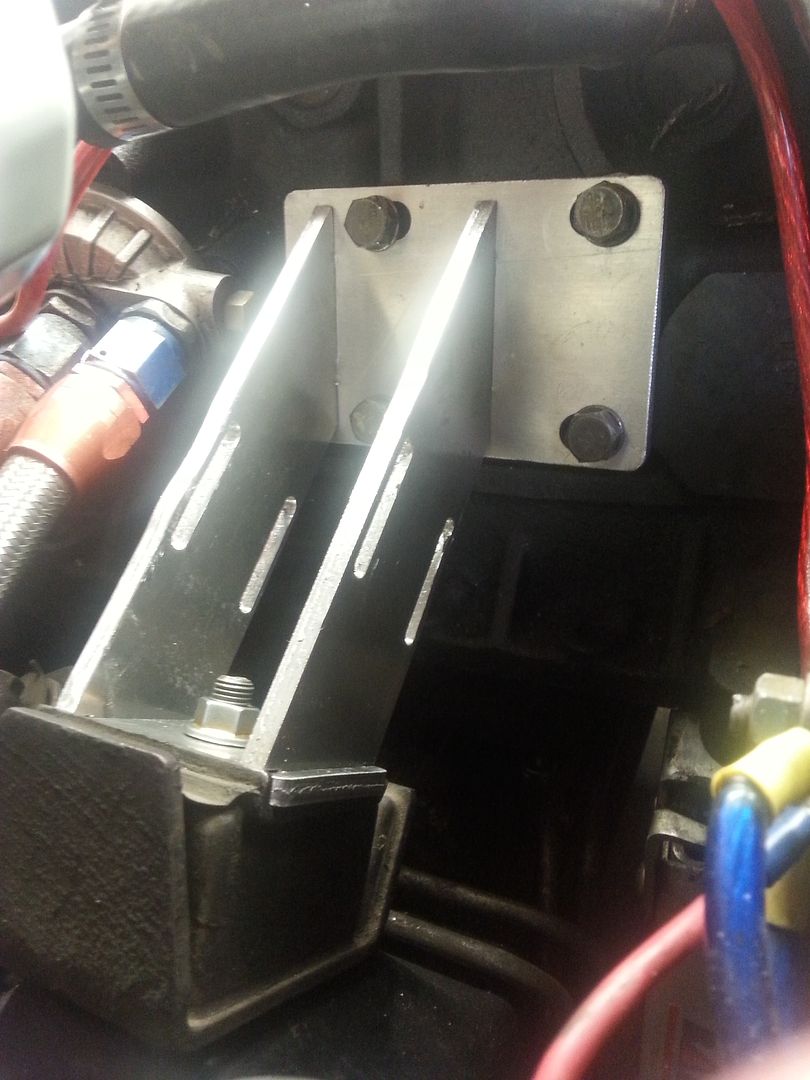

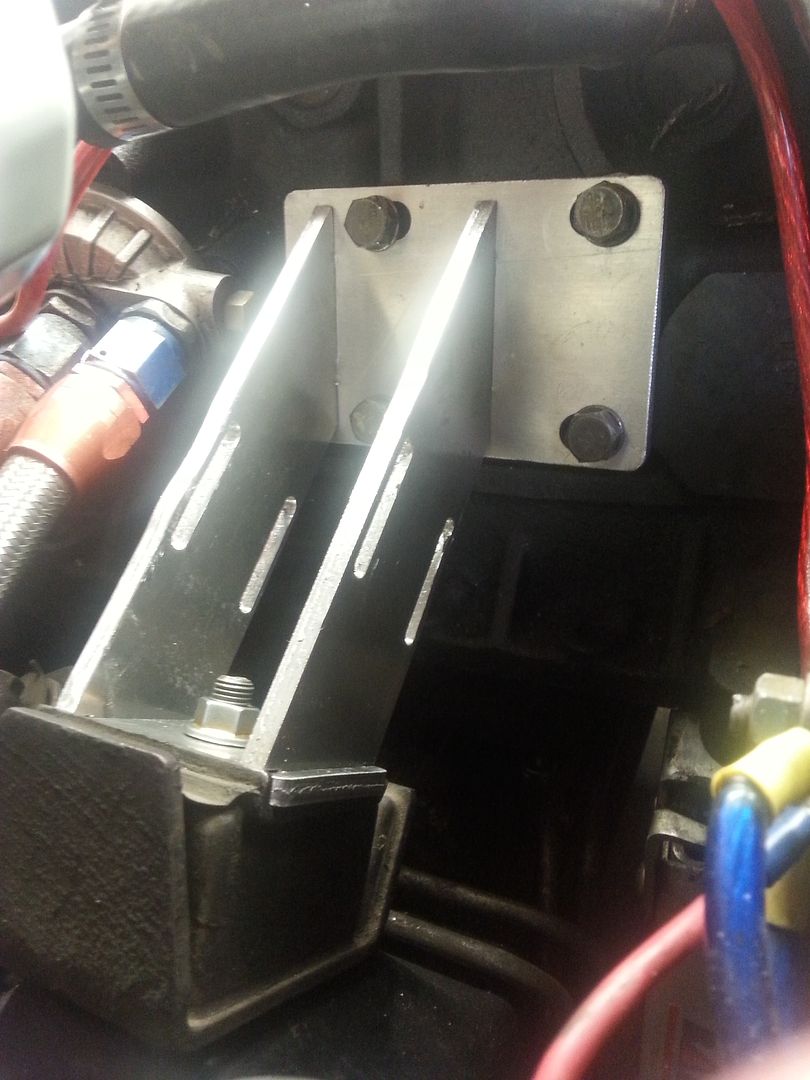

I put a scissor jack under the left hand side of the motor to hold it in place, to make a sample mount I got some 6mm ali and made a flange to bolt onto the block and a flange to bolt on to the mount then made a cardboard template, scanned it and loaded it into Solidworks, made up two side pieces and this is what it looks like, there are two more braces to go in the empty slots that I haven't cut out yet. I'm planning on getting all the bits cut out of 6mm stainless to build the mounts for the white car with, the 6mm ali mount seems reasonably strong so I might finish up the ali "sample" mounts and run them on the black car for a while.

The engine flange and mount flange are both slotted and the side pieces have male bits 5mm tall that go into the slots so everything interlocks and I can fill up the extra 1mm on the rear side of the flanges with weld.

Took the compressor cover off the turbo to see how much oil was actually in there and there wasn't a lot, gave it a good clean out.

I've been thinking about what to do with the motor, I might pull the bottom end out of the car and combine the good crank and oil pump out of this one with the other block and CP forged pistons that are coated that have been at the engine shop for about 18 months now, I'll get some forged rods too. I've got a set of ARP main studs and the ARP head studs that I was running on the original motor.

While I've had access I decided to redo the engine mounts, I was never happy with my box section mount, the position was fine it was just the construction of the mount and the packing that I had to use that wasn't good.

I put a scissor jack under the left hand side of the motor to hold it in place, to make a sample mount I got some 6mm ali and made a flange to bolt onto the block and a flange to bolt on to the mount then made a cardboard template, scanned it and loaded it into Solidworks, made up two side pieces and this is what it looks like, there are two more braces to go in the empty slots that I haven't cut out yet. I'm planning on getting all the bits cut out of 6mm stainless to build the mounts for the white car with, the 6mm ali mount seems reasonably strong so I might finish up the ali "sample" mounts and run them on the black car for a while.

The engine flange and mount flange are both slotted and the side pieces have male bits 5mm tall that go into the slots so everything interlocks and I can fill up the extra 1mm on the rear side of the flanges with weld.

Re: DJZ's 280ZX

Finally managed to get back out to the garage today and made the two braces for the middle of the mount, it's actually come out pretty good I think. I'll try and get down to work tomorrow to weld it up so I can start on the left hand side mount. I'm a little bit worried about the thickness of the aluminium at the top of the top bolt holes but I think it'll be okay, the stainless ones will definitely be okay.

- gingofthesouth

- Site Admin

- Posts: 1932

- Joined: Tue Mar 23, 2010 4:06 pm

- aka: Ging

- Location: Lower Hutt

- Contact:

Re: DJZ's 280ZX

Love your work. Almost makes me want to pack in the startup I have been building up for that quick money back at work to finish off my 510!

Be interested to know how well that Aluminium mount handles a thrashing. I know you say you are making some stainless ones, but if the aluminium ones are strong enough, would you just keep make them for both cars?

Be interested to know how well that Aluminium mount handles a thrashing. I know you say you are making some stainless ones, but if the aluminium ones are strong enough, would you just keep make them for both cars?

My orangatang 510 here.

Re: DJZ's 280ZX

The black car is already certed so I can play with the mounts without too much trouble, with the white car I'll run the stainless mounts for cert as I don't know whether the ali ones would be okay or not. I plan on making some staino ones to sell if they work out right.gingofthesouth wrote:Love your work. Almost makes me want to pack in the startup I have been building up for that quick money back at work to finish off my 510!

Be interested to know how well that Aluminium mount handles a thrashing. I know you say you are making some stainless ones, but if the aluminium ones are strong enough, would you just keep make them for both cars?

- blitzballa

- Financial Member

- Posts: 160

- Joined: Tue Mar 04, 2014 2:41 pm

- aka: James

- Location: Christchurch

- Contact:

Re: DJZ's 280ZX

I recently made some ali engine mounts for an SR20 with a T3T4 very very similar in design to what you have except that it was 5mm and I had slotted them considerably more (for weight). I did FEA on them and was able to confirm that they were good to about 420 NM of torque. If your ally welding is pretty good I would say yours would be even stronger given the extra thickness and less slotting. Don't know how NZTA feel about it but if you would like I can see if I can pull out the results out of my work computer and send them to you. Do you have MATLAB?DJZ wrote:The black car is already certed so I can play with the mounts without too much trouble, with the white car I'll run the stainless mounts for cert as I don't know whether the ali ones would be okay or not. I plan on making some staino ones to sell if they work out right.gingofthesouth wrote:Love your work. Almost makes me want to pack in the startup I have been building up for that quick money back at work to finish off my 510!

Be interested to know how well that Aluminium mount handles a thrashing. I know you say you are making some stainless ones, but if the aluminium ones are strong enough, would you just keep make them for both cars?

Re: DJZ's 280ZX

That's interesting, at least I'm on the right track! I don't have MATLAB, I can barely operate Solidworks.blitzballa wrote:I recently made some ali engine mounts for an SR20 with a T3T4 very very similar in design to what you have except that it was 5mm and I had slotted them considerably more (for weight). I did FEA on them and was able to confirm that they were good to about 420 NM of torque. If your ally welding is pretty good I would say yours would be even stronger given the extra thickness and less slotting. Don't know how NZTA feel about it but if you would like I can see if I can pull out the results out of my work computer and send them to you. Do you have MATLAB?

I got the bits finished to mock up the left hand side mount this evening, I bought some new 3 flute carbide end mills and they are amazing, managed to double the feed speed and get almost as good a finish with a roughing end mill as with the HSS ones I was using before and can probably go even faster, everything I buy from now on will be carbide.

I'll post some pictures tomorrow but the mount went straight on, everything seems to line up pretty well so I just need to cut out the two support pieces and weld it together.

Re: DJZ's 280ZX

Motor is pretty much ready to come out, need to get the 2+2 out of the way so I can roll this outside to do it though.

Got the new rings from the States for this block, got the correct ones first time this time which is good.

Swapped the horn button for the one that I used to have on the DR which I think is a genuine Momo one, I bought what I thought was a genuine one for the Z but it doesn't look/feel quite right to me. It adds a tiny bit of colour (yellow) to the interior as well.

Haven't done much else to it though, charged the battery and that is about it.

When the final motor goes in I want to tidy up a bunch of stuff, the idle control, the bits of the loom that I have mucked around with, I will be replacing the intercooler with something a bit smaller and I'll tidy up the intercooler piping, make a new exhaust out of stainless, maybe repaint the engine bay again with some paint that sticks.

Got the new rings from the States for this block, got the correct ones first time this time which is good.

Swapped the horn button for the one that I used to have on the DR which I think is a genuine Momo one, I bought what I thought was a genuine one for the Z but it doesn't look/feel quite right to me. It adds a tiny bit of colour (yellow) to the interior as well.

Haven't done much else to it though, charged the battery and that is about it.

When the final motor goes in I want to tidy up a bunch of stuff, the idle control, the bits of the loom that I have mucked around with, I will be replacing the intercooler with something a bit smaller and I'll tidy up the intercooler piping, make a new exhaust out of stainless, maybe repaint the engine bay again with some paint that sticks.

Re: DJZ's 280ZX

Oh and I'm not sure if I mentioned it before but I bought some Recaro seat rails for this which should be turning up this week, I still want to try and put the FD RX7 seats into one of these things seeing as I have them, if that gets too hard I'll try and find a pair or even a single nice looking Recaro like the one I had in the DR.