Not My Photos but this is the idea!

remove gear from A-series distributor and fit to the E-series distributor

Create new (or modify existing) housing clamp-down

Insert distributor with correct timing

Connect the two wires and enjoy maintenance free driving (no more yearly points changing)

[edit]

Gear Changeover

E15 doesn't use a gear, but is otherwise nearly identical to A15 distributor:

4537.jpg

Top dizzy is from E15 to which the gear has been fixed, while the lower one is from A10/A12.

3948.jpg

The E15 has been converted for A series. Note that it seems to fractionally longer that the A series when comparing shafts -- but that's because the plate is not installed yet.

Using a 3mm pin punch, remove the roll pin from an A-series distributor. Remove the gear from the shaft. Do the same for the retaining ring on the E-series distributor. Fit the A-series gear onto the E-series distributor shaft. Before drilling a new hole for the roll pin, ensure there is sufficient end float at the top of the gear. (Use a shim or similar when drilling). The clearance required is minimal but is needed to ensure the distributor spins freely. What is the spec for this clearance on the original distributor?

4604.jpg

You don't need to modify the dizzy casting to install in an A-series -- it fits in just fine. However, the E-series distributor's hold-down bracket doesn't line up with the block's bolt hole.

Solution:

- modify the distributor

or

- rather than modify the distributor, make a simple bracket. Then leave the dizzy's own bracket hanging off the distributor unused. It is cast in with the housing so doesn't come off.

Use any single one of the following methods. For a more OEM look, you can drill, grind, cut and otherwise modify the E15 dizzy casting. But there's no need to modify the housing. Your choice.

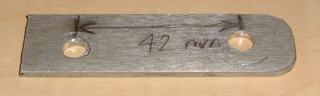

For Early blocks the simplest method by far is to drill two 6mm (1/4 inch) holes exactly 42 mm apart:

2 or 3 mm thick aluminum

hole centers: 42 mm

overall size approximately 65 x 20 mm

Fit the destributor in over the stock A12 dizzy plate, and bolt the bracket in like so: